Soil pH is often called the "master variable" of soil health. It dictates nutrient availability, microbial activity, and root health. In traditional farming, managing pH meant manual sampling, lab delays, and broad-spectrum chemical application. Today, the IoT soil pH sensor is revolutionizing this process, turning static data into dynamic, actionable intelligence.

For modern agricultural decision-makers, understanding the technical architecture and application of smart agriculture pH monitoring is no longer optional—it is the baseline for high-efficiency farming.

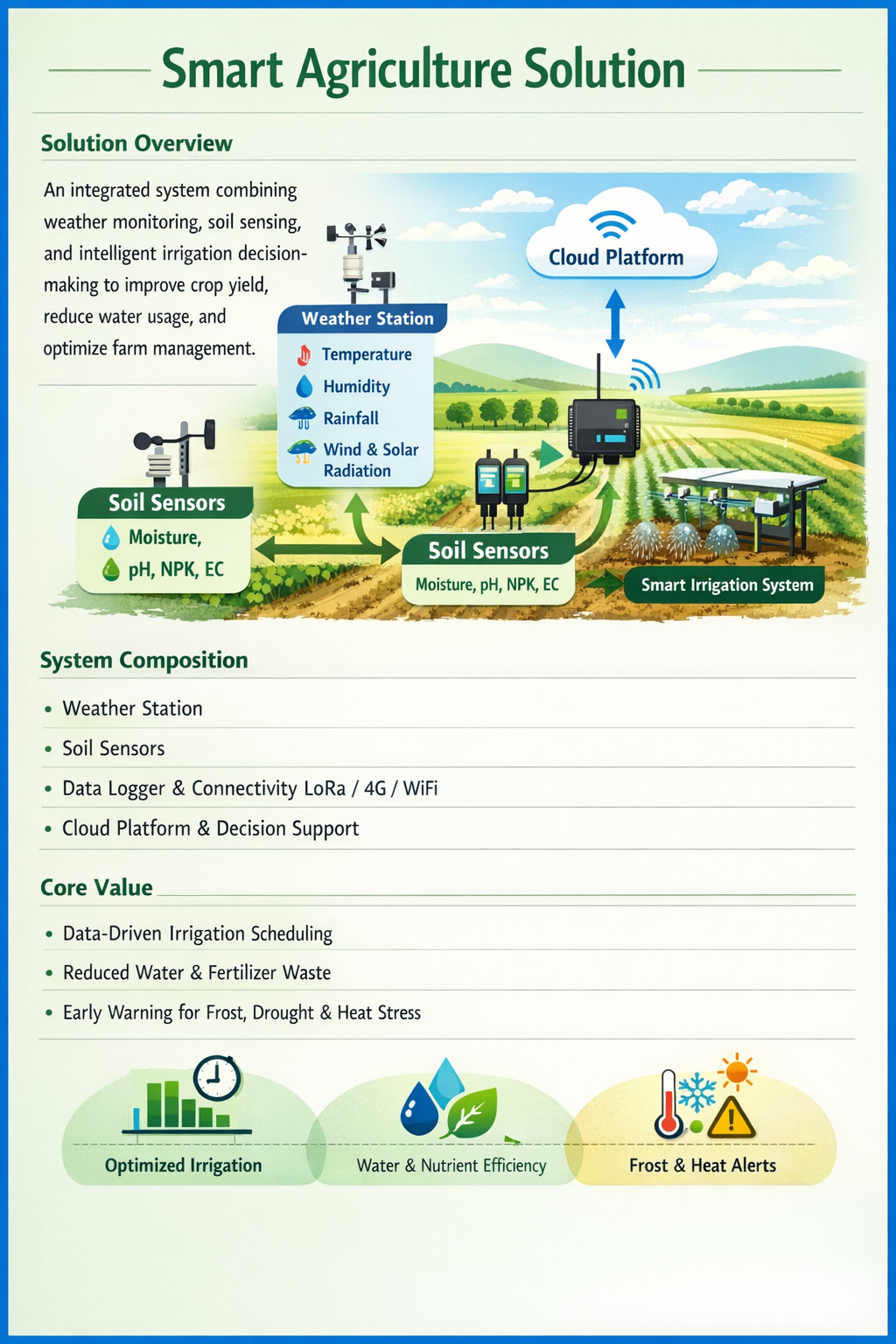

An effective IoT monitoring system is not just a probe in the ground; it is a three-tier architecture designed for reliability in harsh environments.

At the ground level, the IoT node consists of an industrial-grade pH probe (often using ISFET or glass electrode technology) combined with a wireless transmitter.

Durability: These sensors must be IP68 rated to withstand moisture, dust, and agrochemicals.

Power Management: Low-power design is critical. Many modern nodes utilize solar assist or long-life batteries capable of running for 3–5 years.

Data Granularity: Unlike manual testing, these sensors capture fluctuations in real-time, defined scientifically as pH = -log10[H+] . This continuous stream of data helps identify rapid changes caused by rain, irrigation, or fertilization that manual sampling misses.

Data transmission in rural areas faces unique challenges regarding range and bandwidth. The gateway acts as the bridge between the field and the internet.

Protocols: Most scalable solutions utilize LoRaWAN, NB-IoT, or Zigbee. LoRaWAN is particularly popular for precision farming with pH sensors due to its long-range (10km+) and low-power capabilities, penetrating dense canopy cover where cellular signals fail.

The raw data is transmitted to a cloud server for processing.

Visualization: Data is rendered onto dashboards accessible via mobile or desktop.

Analytics: Algorithms compare current readings against crop-specific thresholds (e.g., Blueberries: 4.5–5.5 pH; Wheat: 6.0–7.0 pH).

API Integration: The platform pushes data to other farm management systems (FMS), automating workflows.

Integrating IoT soil pH sensors enables three critical operational shifts:

Soil acidification can occur rapidly due to nitrogen fertilization. IoT systems provide immediate alerts when pH levels drift outside the optimal range. This prevents "nutrient lockout"—a condition where nutrients are present in the soil but chemically unavailable to the plant due to incorrect pH.

Precision farming with pH sensors allows for Variable Rate Technology (VRT). Instead of blanketing an entire field with lime or sulfur, farmers can use pH maps generated by IoT sensors to apply amendments only where needed. For example, if Zone A has a pH of 6.5 (ideal) and Zone B has 5.5 (too acidic), the system directs the spreader to apply lime only to Zone B.

Water quality (pH and alkalinity) heavily influences soil pH. Advanced IoT setups integrate soil sensors with irrigation controllers. If the soil pH rises too high, the system can automatically adjust the fertigation mix (injecting acid) to balance the water pH before it hits the root zone.

Scenario: A large-scale blueberry orchard implemented a LoRaWAN-based smart agriculture pH monitoring system, deploying 50 sensor nodes across 100 hectares. Instead of annual manual testing, data was collected every 30 minutes.

Key Performance Indicators:

Yield Increase (+12%): By maintaining the optimal acidic range (4.5–5.5), the farm maximized iron and nitrate uptake, resulting in healthier crops and higher output.

Resource Savings (-20%): The farm significantly reduced lime and acidifier usage. By utilizing VRT based on sensor data, chemicals were applied only to specific zones rather than the entire field.

Labor Reduction (90%): The system eliminated the need for manual soil sampling, sample preparation, and shipping logistics to laboratories.

ROI Analysis:

While the initial hardware cost is higher than manual kits, the Return on Investment (ROI) is typically realized within 18 to 24 months through fertilizer savings and yield consistency. Furthermore, long-term data logging aids in land value assessment and environmental compliance reporting.

The era of guessing is over. The IoT soil pH sensor is not merely a gadget; it is a foundational tool for data-driven agronomy. By deploying these sensors, agricultural enterprises can transition from reactive farming—fixing problems after visual symptoms appear—to proactive farming, where soil health is optimized minute by minute.

For decision-makers, the path forward is clear: integrate precision farming with pH sensors to secure supply chains, reduce chemical footprints, and ensure the sustainability of the land for future harvest cycles.

Discover why UV data is essential in environment

Discover how ultrasonic wind sensors enhance sol

Discover why CO₂ monitoring is critical for smar

Contact: Molly

Phone: +86-17775769236

Tel: 86-0731-85117089

Email: molly@codasensor.com

Add: Building S5, Aux Square, Yuelu District, Changsha City, Hunan Province, China

We chat