The rapid global expansion of Photovoltaic (PV) power generation has shifted the industry's focus from mere installation to maximizing long-term efficiency and Return on Investment (ROI). While sunlight is the fuel, temperature is the ultimate regulator of a solar array’s performance.

To accurately interpret and manage the massive power output of a modern solar farm, operators must rely on a trifecta of sophisticated sensors: high-precision Solar Panel Temperature Sensors (often utilizing patch sensor technology) and comprehensive Automatic Weather Stations (AWS). These tools provide the granular data necessary for intelligent operations, predictive maintenance, and strategic financial planning.

The relationship between temperature and photovoltaic power output is inverse: as the temperature of the solar cell increases, its efficiency (and thus, its power output) decreases. This is known as the Temperature Coefficient, typically resulting in a 0.3% to 0.5% loss in power for every 1°C rise above the standard testing condition (STC) of 25°C.

A Solar Panel Temperature Sensor, frequently implemented as a thin, high-accuracy patch sensor adhered to the back surface of the PV module, provides the true operational temperature of the silicon cells. This direct measurement is critical for several applications:

Accurate MPPT (Maximum Power Point Tracking): Inverters rely on module temperature data to calculate the optimal voltage and current (Maximum Power Point) for extracting peak power. Using ambient air temperature (measured by the AWS) instead of the actual module temperature can lead to significant power underperformance and lost revenue.

Hotspot Identification: The primary function of a patch sensor is to detect localized overheating caused by cell defects, microcracks, or partial shading. These hotspots are serious safety and financial risks, leading to premature degradation and potential fire hazards. Real-time temperature spikes flagged by the sensor trigger immediate diagnostic alerts.

Warranty and Degradation Analysis: Accurate, traceable module temperature data is essential for validating manufacturer warranties and definitively determining if performance loss is due to defects or environmental factors.

While the patch sensor provides the internal state of the panel, the Automatic Weather Station (AWS) provides the complete external environmental context required for performance analysis and system protection.

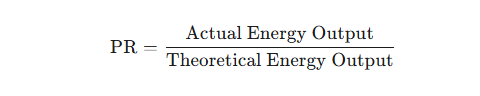

The most vital function of the AWS is to enable the calculation of the plant’s Performance Ratio (PR). The PR is the true measure of a solar farm’s quality and efficiency, isolating system losses from weather effects.

The AWS measures the key variables needed for the "Theoretical Energy Output" denominator, including:

Solar Irradiance: Measured by a Pyranometer (like the CODA CDG-10B), this is the direct input power.

Ambient Temperature: Used to understand the broader thermal environment.

Wind Speed and Direction: Wind flow directly impacts cooling. High wind means lower module temperature and higher efficiency, a crucial factor in PR calculation.

Rainfall and Humidity: Used for soiling prediction and managing system vulnerability to adverse conditions.

The Challenge: A large-scale PV farm located in a semi-arid desert region was consistently reporting a Performance Ratio (PR) below contractual obligations, despite high irradiance. The initial system only monitored ambient temperature.

The Solution:

Deployment: High-accuracy patch temperature sensors were installed on 5% of all module types across the array, and CODA Automatic Weather Stations (including the CDG-10B Pyranometer and CDF-10A/21A wind sensors) were strategically placed to capture micro-climate variations.

Data Revelation: The data revealed that due to minimal wind and intense heat reflection from the ground, the actual module back-surface temperature was on average

Action & Result: By integrating the accurate module temperature data into the inverters' MPPT algorithms, the plant's operational settings were recalibrated. This correction alone resulted in a

Question | Answer |

|---|---|

Why is patch sensor temperature better than ambient temperature? | Ambient temperature only tells you the air condition. The patch sensor measures the actual working temperature of the module's back sheet, which can be significantly higher (up to |

How often should I clean my modules based on AWS data? | Cleaning cycles should be optimized using the AWS's irradiance and rainfall data. When the difference between the actual power output and the theoretical power (calculated using real-time irradiance and temperature data) exceeds a set threshold (e.g., |

How many temperature sensors do I need for my PV farm? | It depends on the size and complexity. A common best practice is to install sensors on at least |

Can AWS prevent safety issues like fires? | Yes. By monitoring extreme weather conditions (e.g., high winds, lightning risk) the AWS provides early warnings to halt maintenance work and stow tracking systems. Furthermore, the temperature patch sensors directly alert the system to potential hotspots before they cause catastrophic module failure or ignite materials. |

In the era of precision agriculture, the efficie

Discover how online pH sensors improve smart agr

Choosing the right online pH sensor is critical

Contact: Molly

Phone: +86-17775769236

Tel: 86-0731-85117089

Email: molly@codasensor.com

Add: Building S5, Aux Square, Yuelu District, Changsha City, Hunan Province, China

We chat